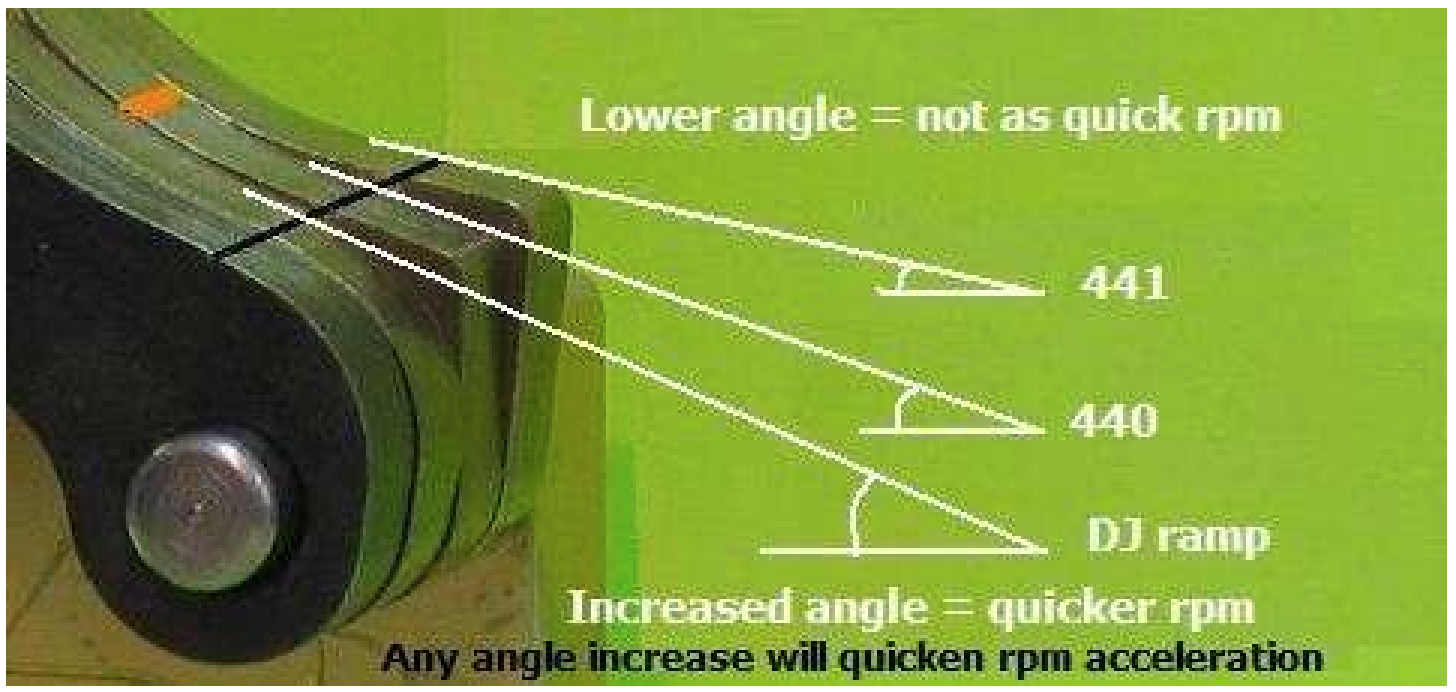

Ramp profile

“Controls the size/magnitude of the shift force”

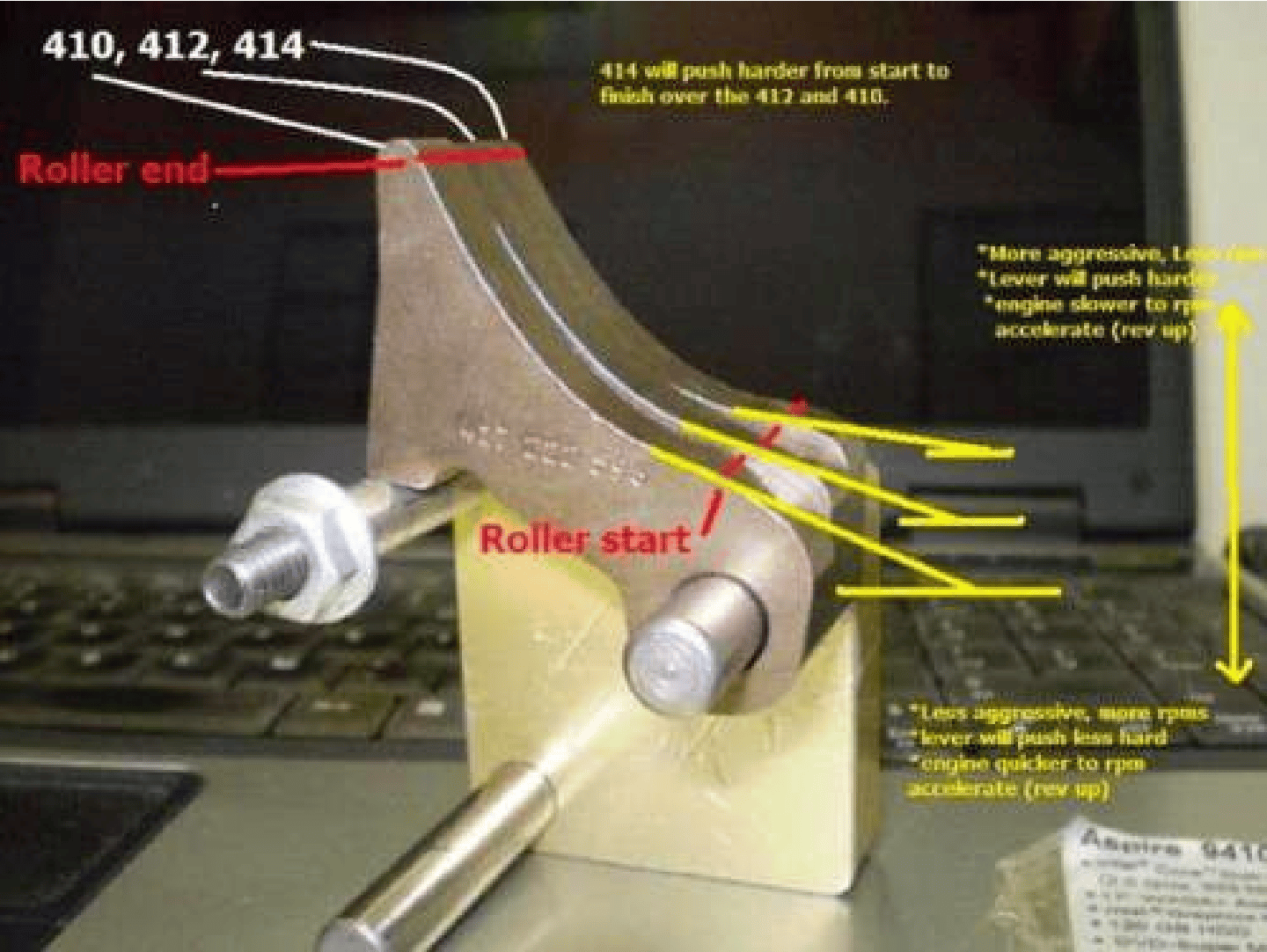

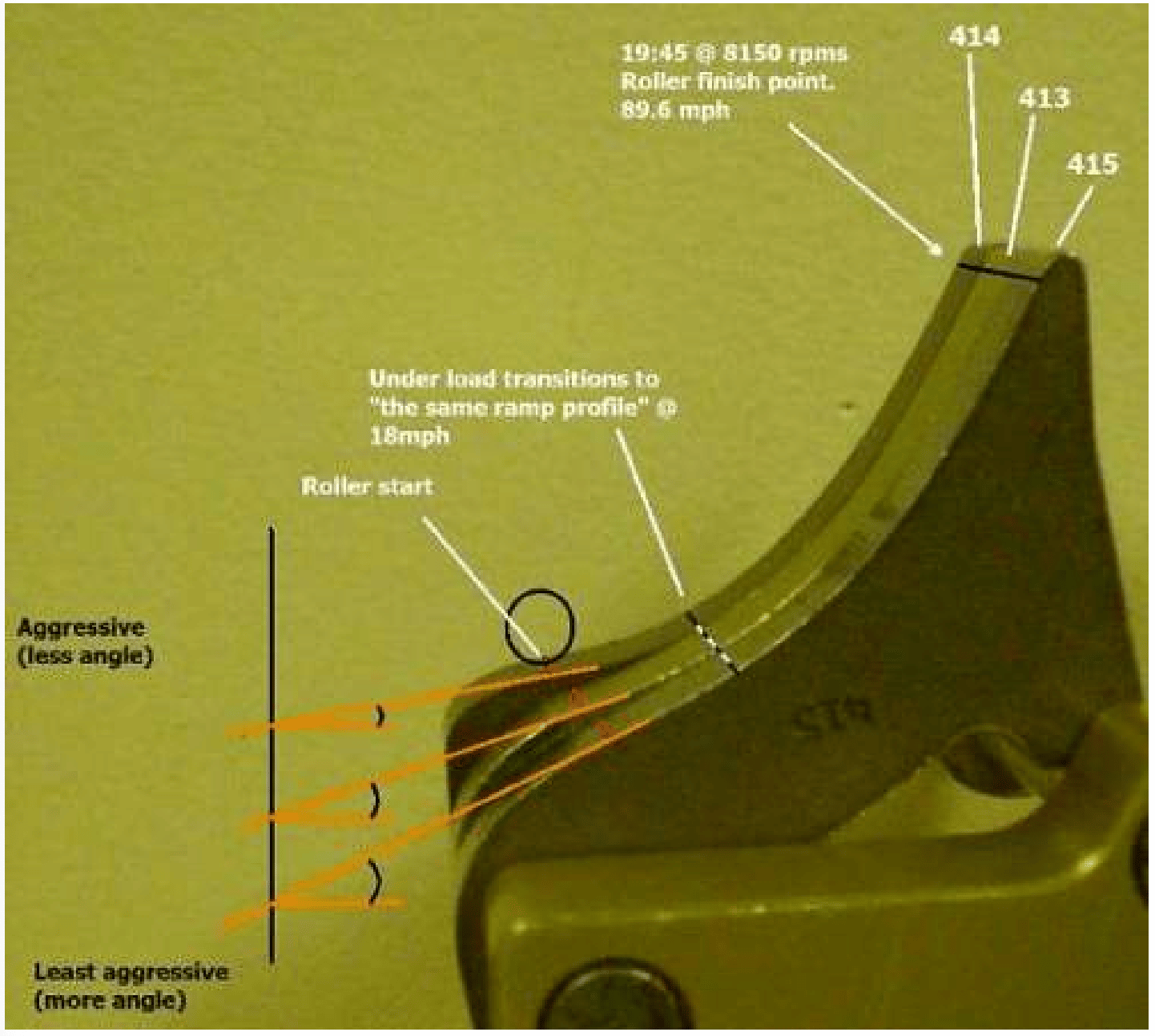

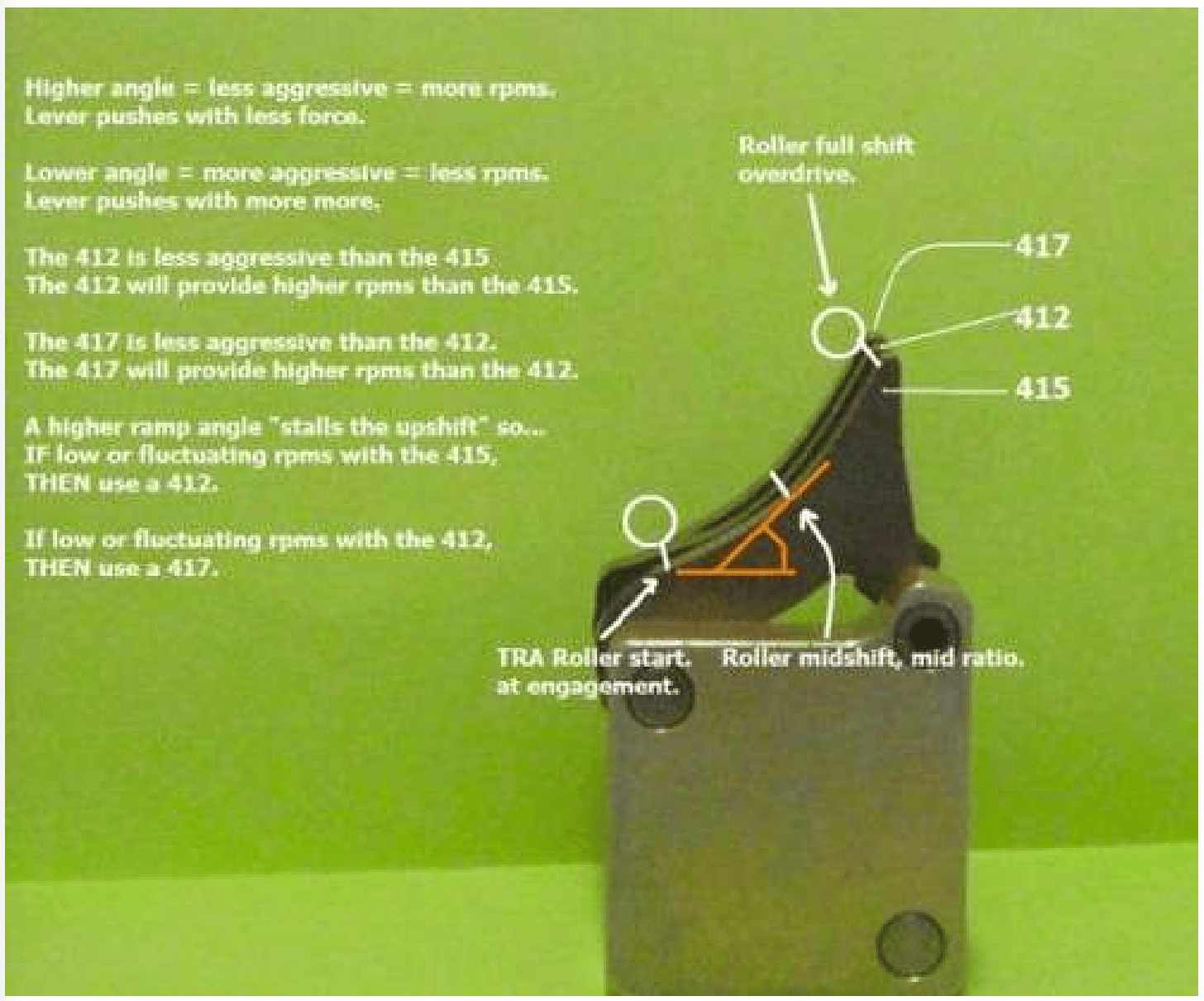

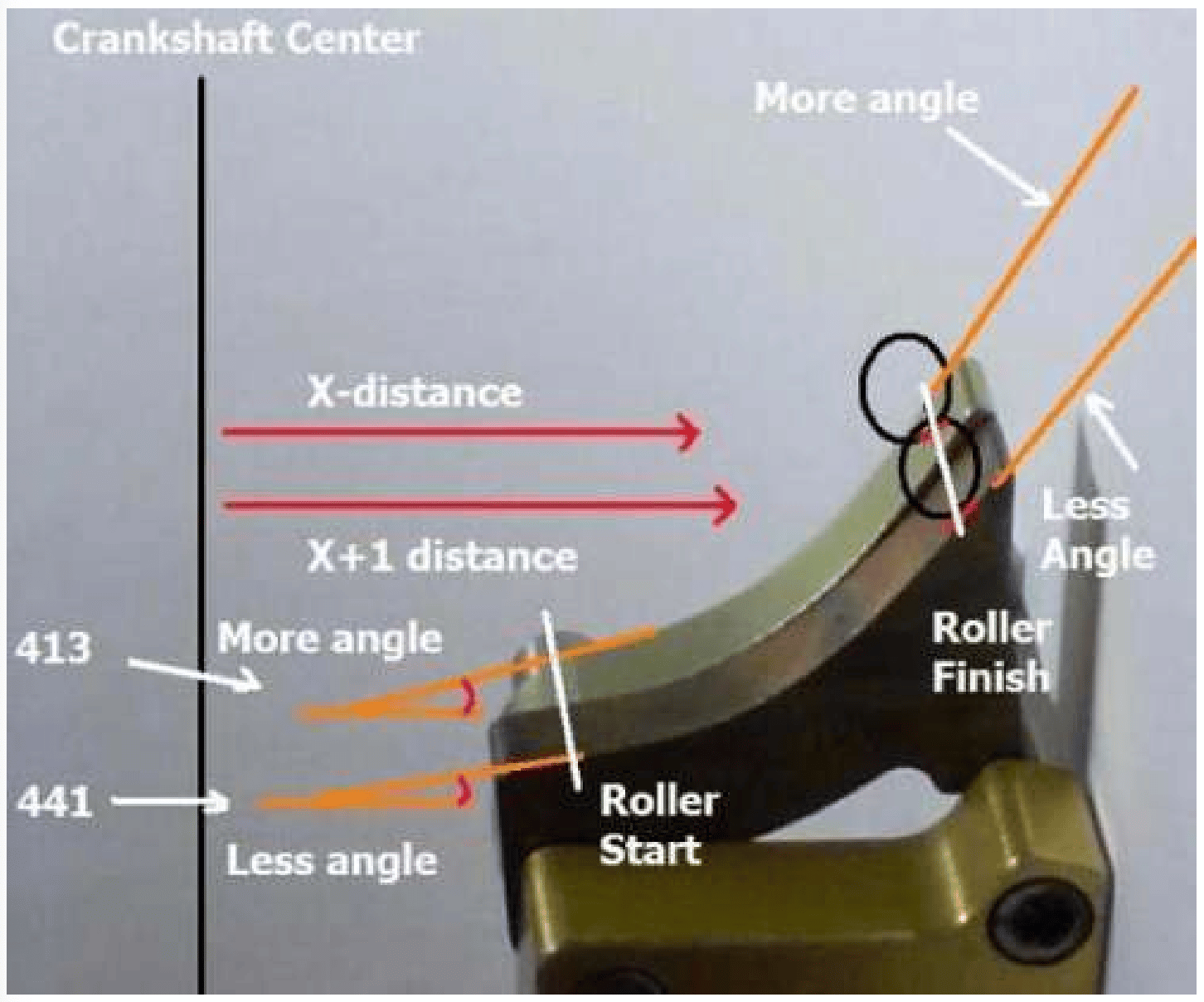

Lower angle will provide more shift force.

Thinner ramp allows the tra lever center of gravity to be farther away from the clutch shaft centerline – Provide more shift force.

Higher angle will provide less shift force.

Thicker ramp allows the tra lever center of gravity to be closer to the clutch shaft centerline – Provide less shift force.

Clickers

“Changes TRA ramp angle” Ramp profile controls the size/magnitude of the shift force.

Determines how quickly the engine will rev/accelerate.

Clicker 6 raises ramp angle to highest point – Quickest engine response

clicker 1 lowers ramp angle to lowerst point – Slowest engine response

Learn what your clickers do for 1)rpms and 2) how the clutch shifts. Cycle them down to 1 and go to 6 and figure out which one allows the cltuch to push the hardest, you feel the best acceleration however have good rpm response when you chop the throttle on off or when the snow load changes.

Angle diagram

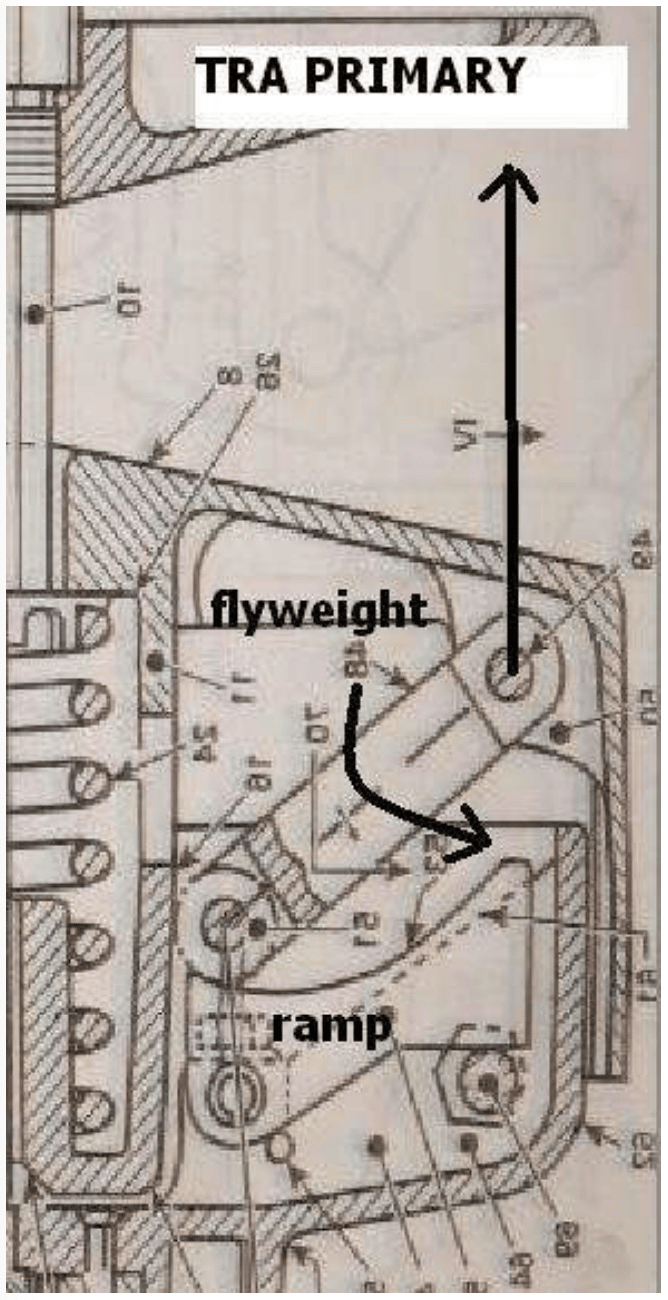

Lever push

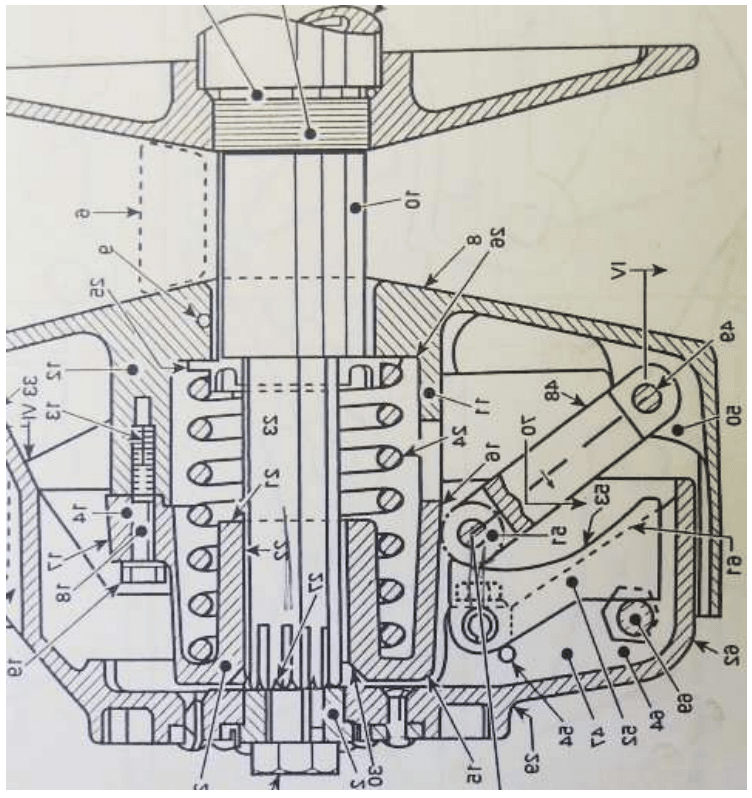

Primary section cutaway

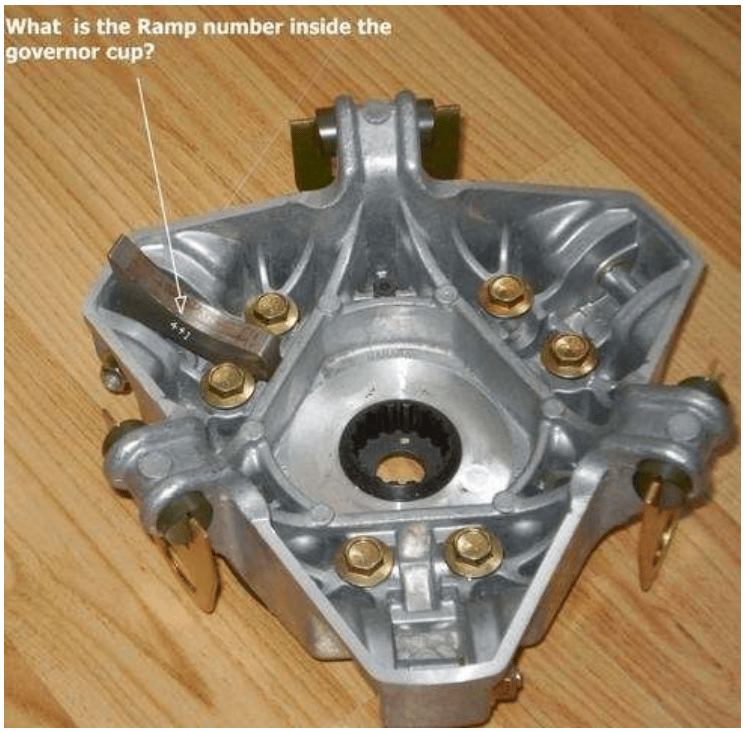

Governor cup illustration

410, 412, 414

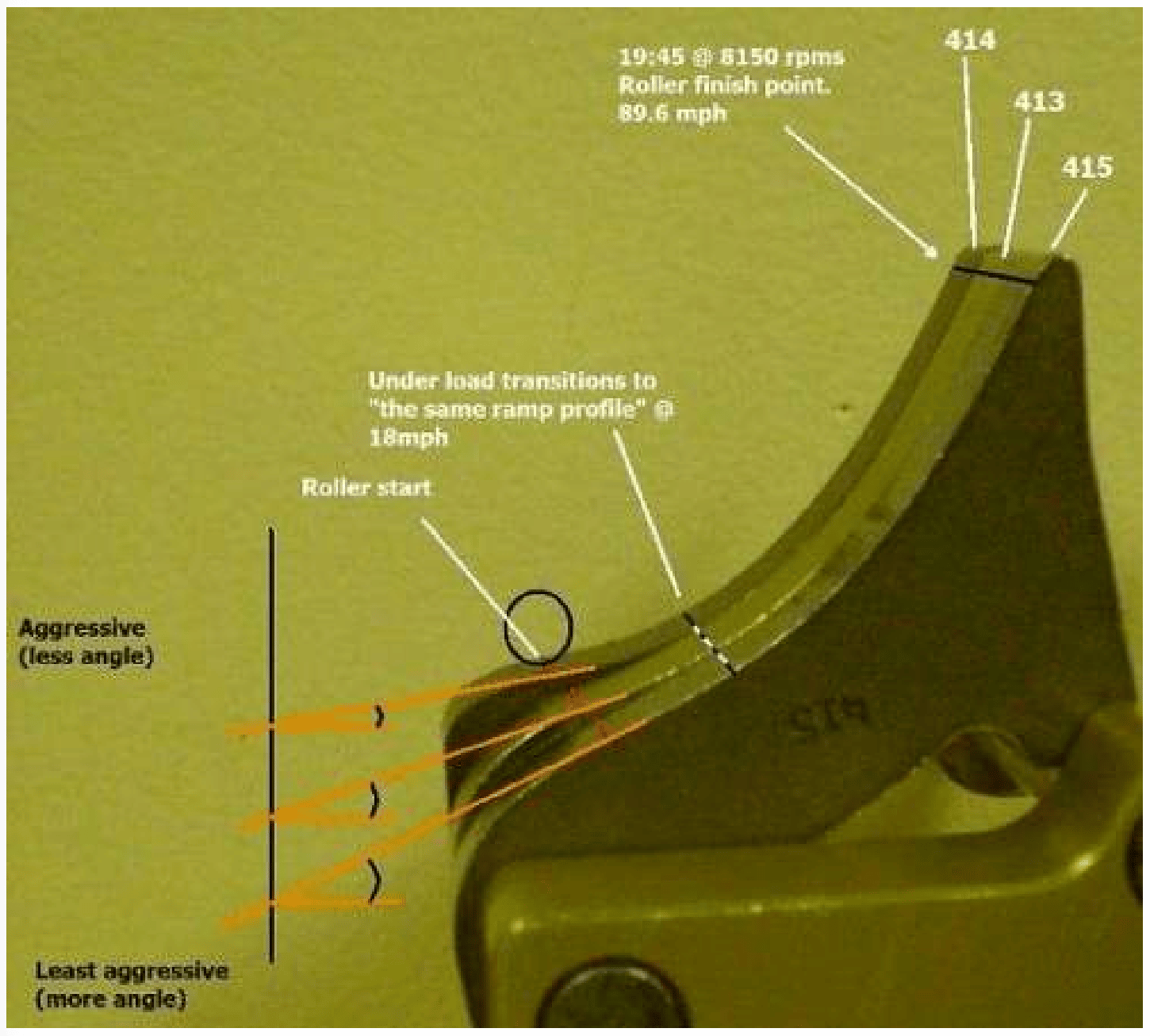

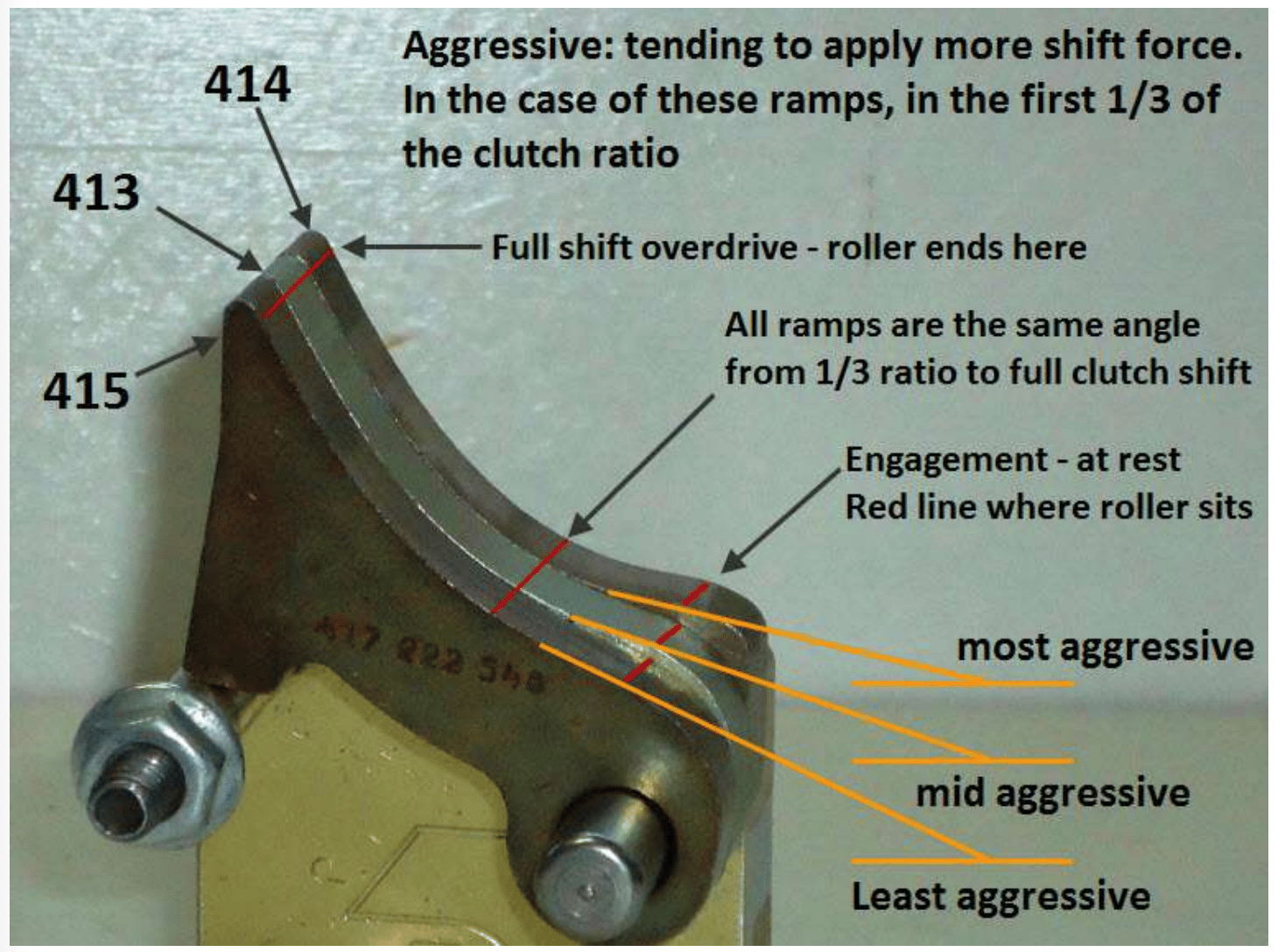

414, 413, 415

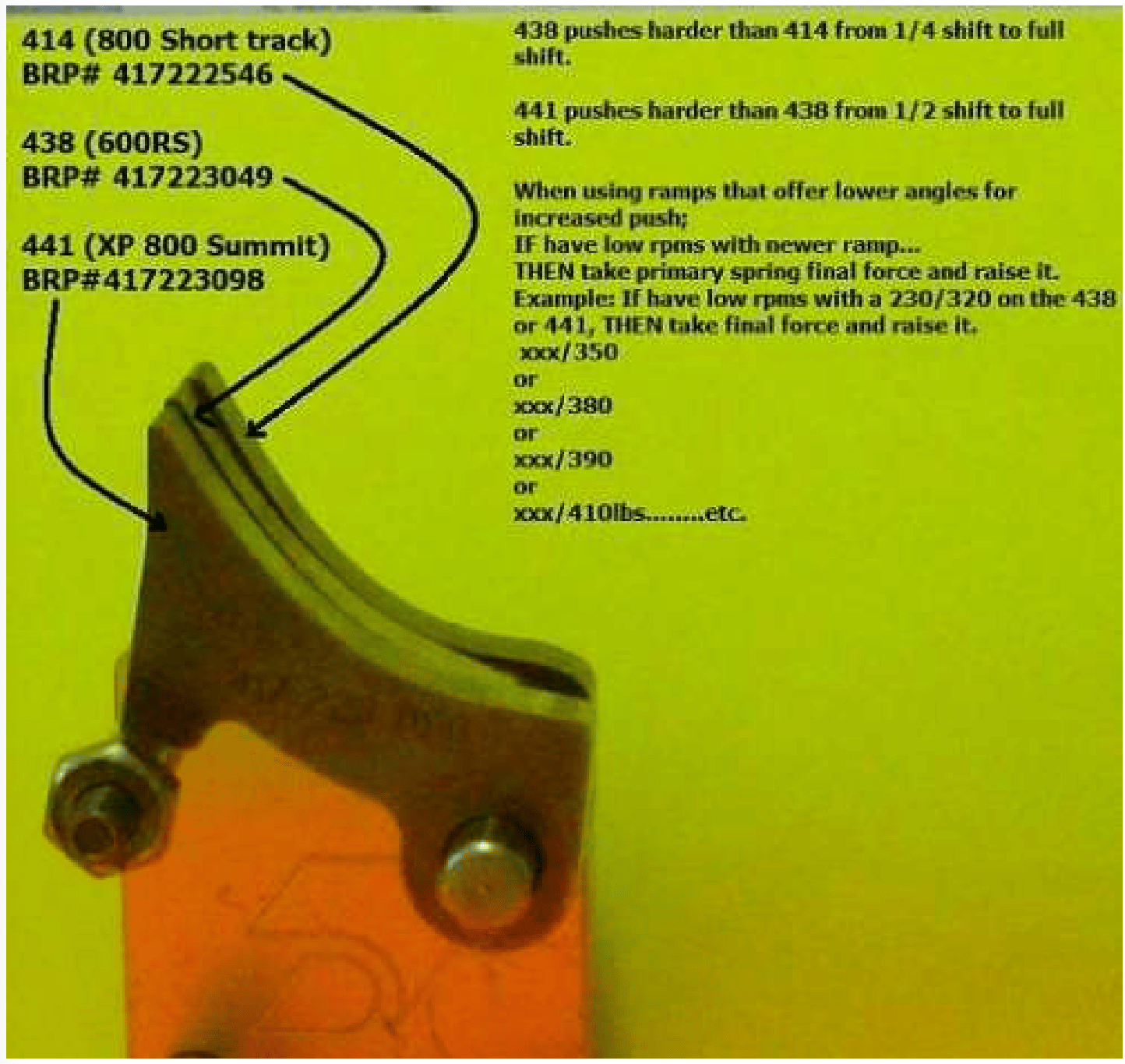

414, 438, 441

417, 412, 415

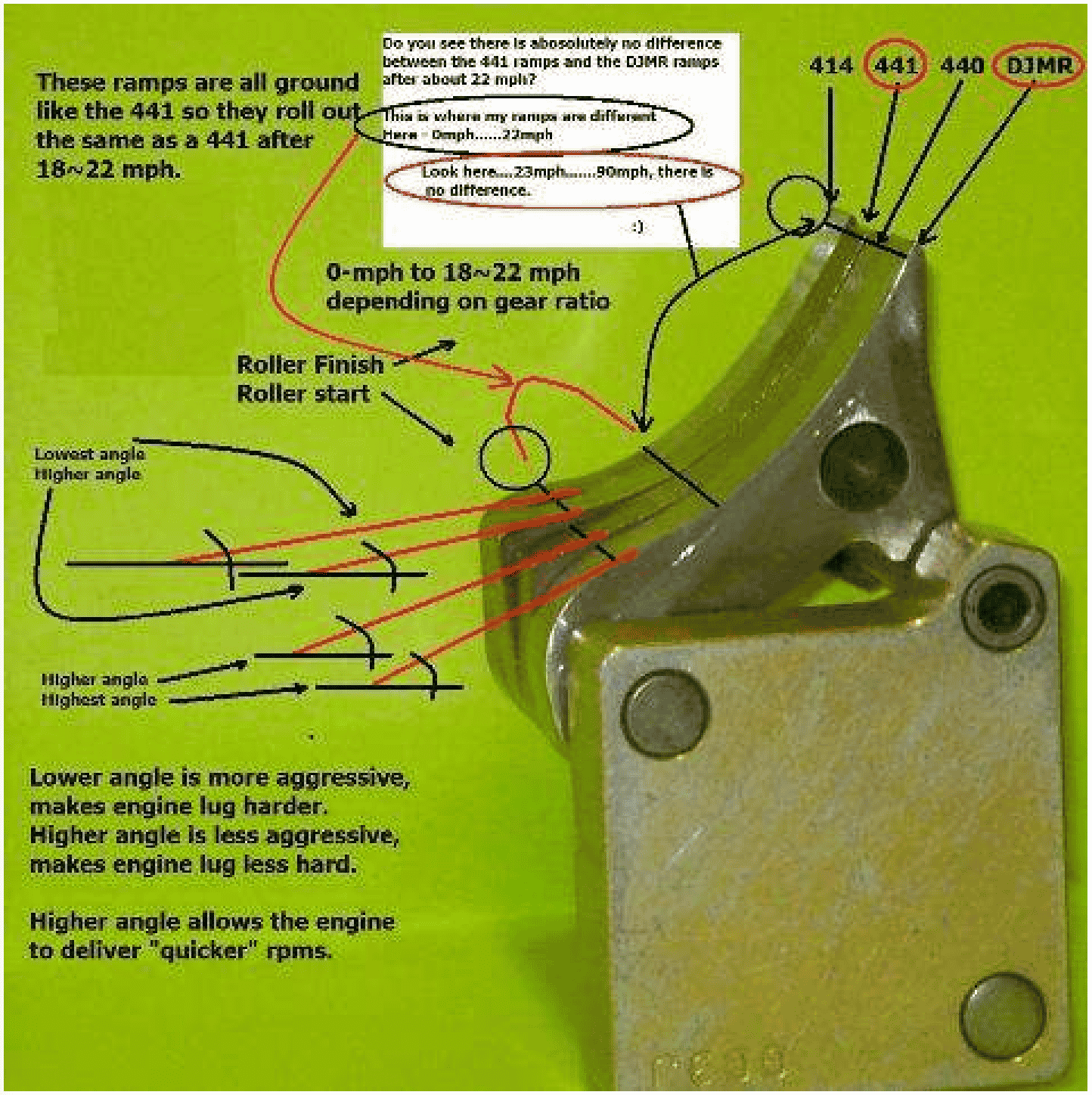

414, 441, 440, DJMR

These particular ramps below, I ground all the ramps to have the same curve as the 441 in the later part of the ramp(s).

What I wanted to do here is have all the ramps maintain their individual start profiles for the first 2/5th of the shift. Then have the last 3/5th of the ramp have the same (441)”push force” to full shift.

413, 438, 441

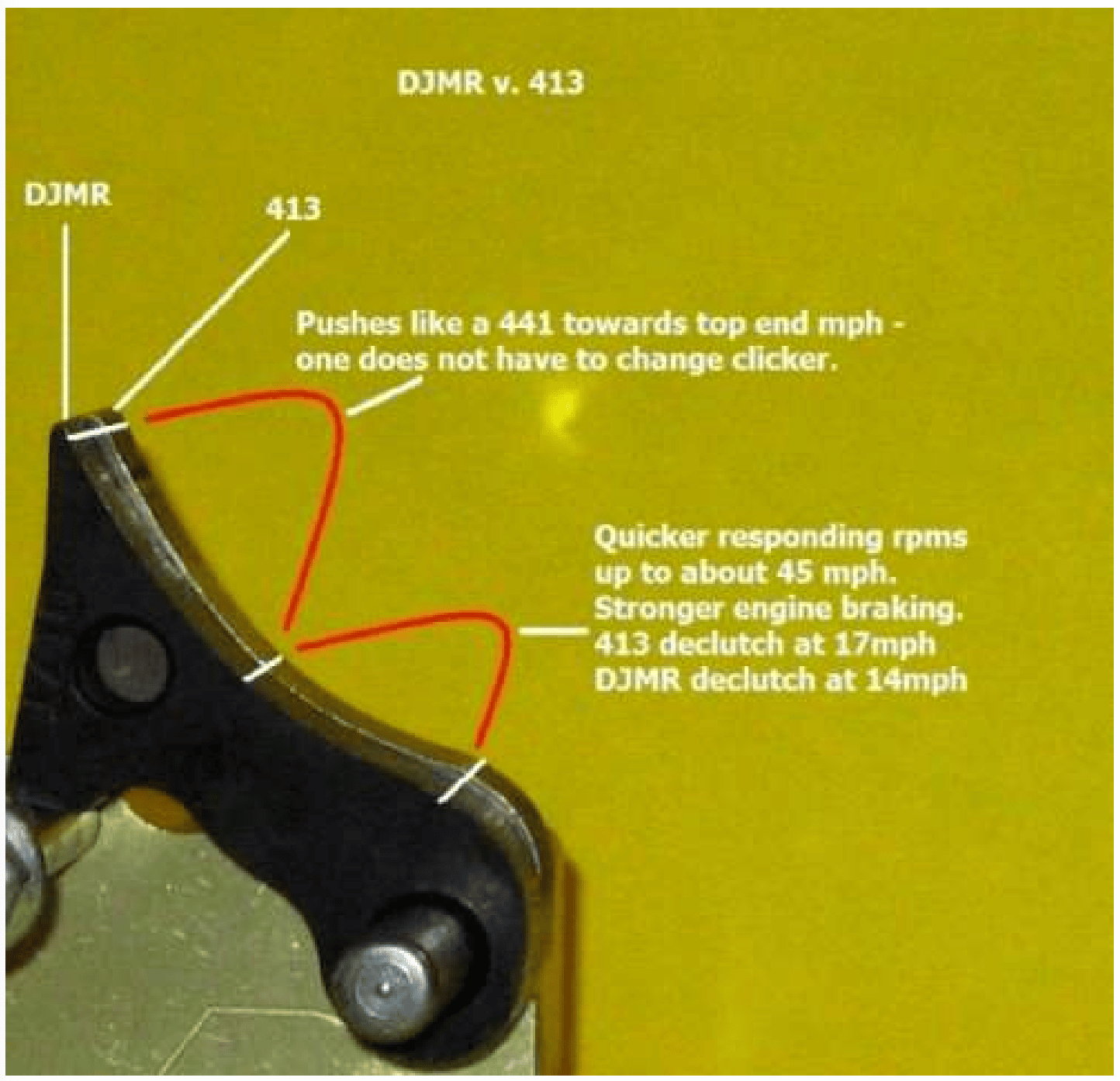

DJMR, 413

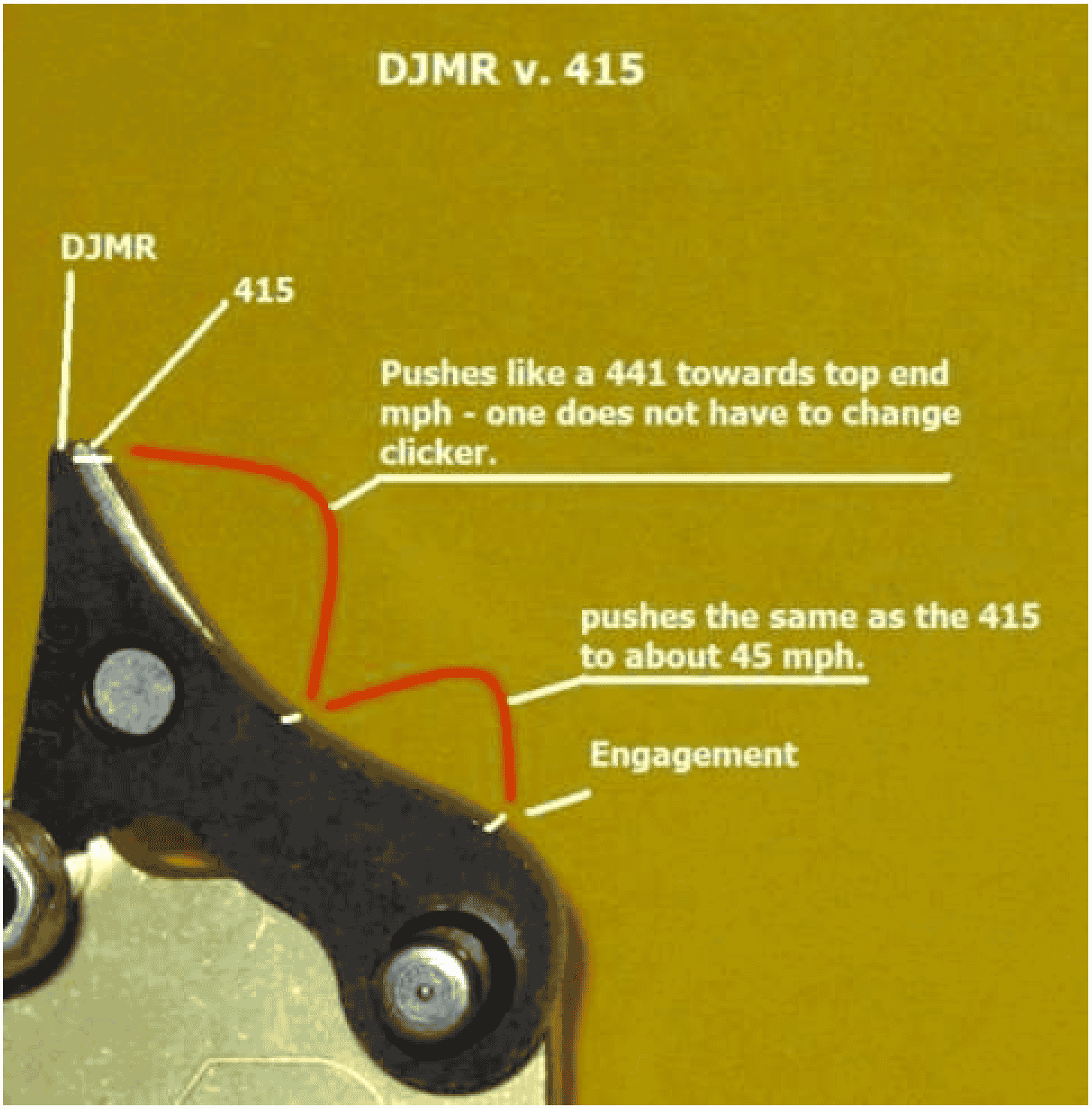

DJMR, 415

413, 441

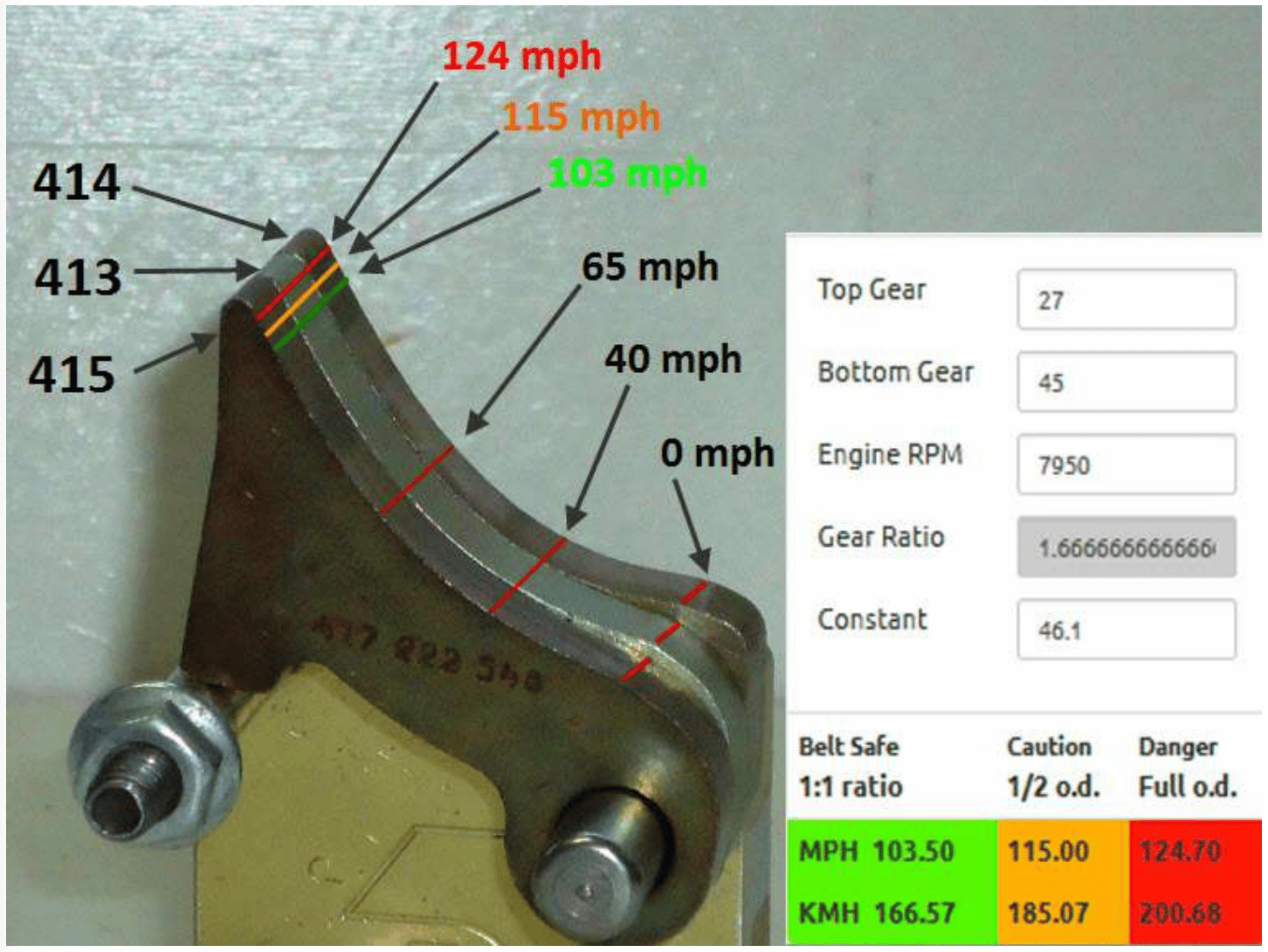

413, 414, 415 on 27:45 gears

More 413, 414, 415

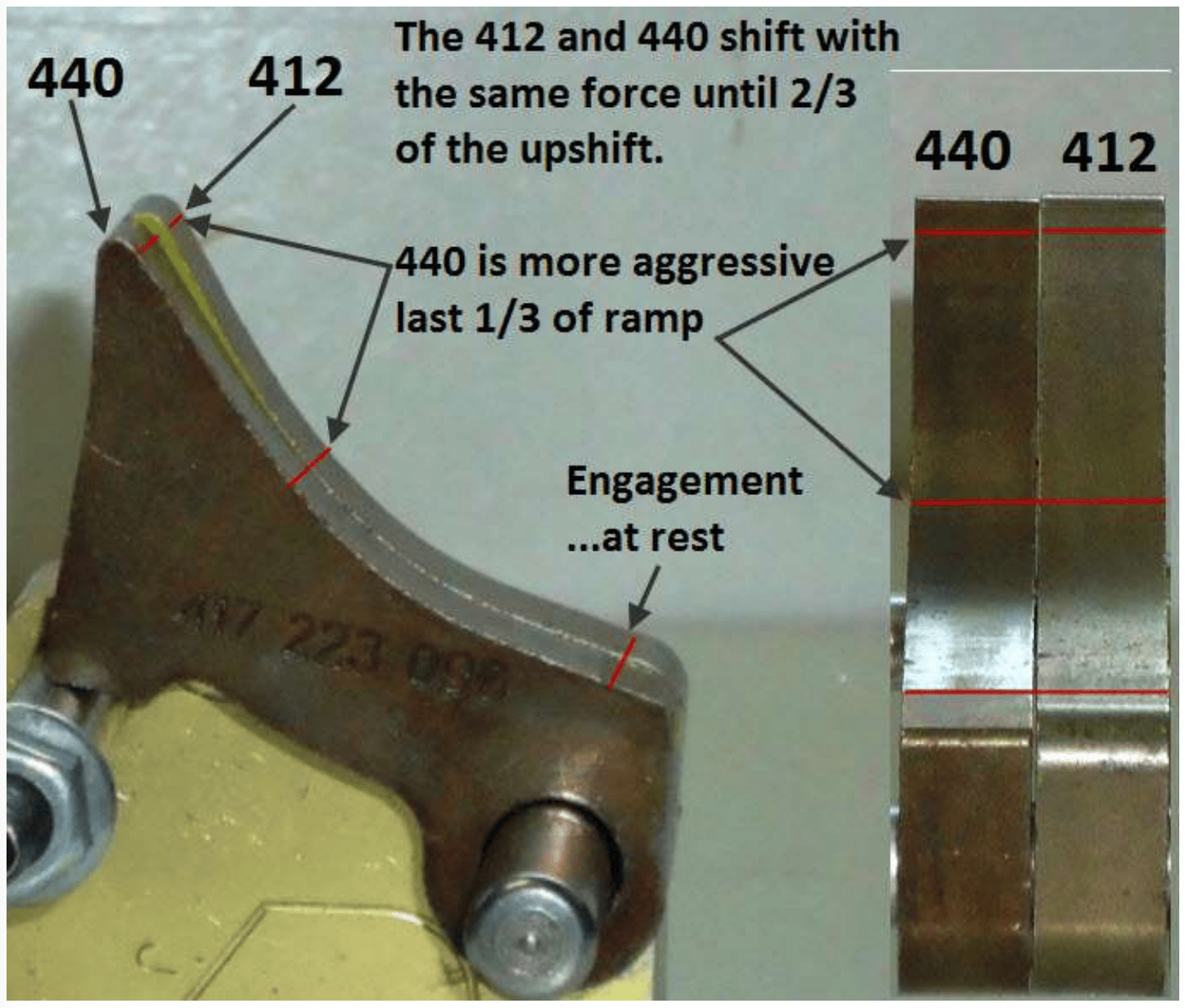

412 v 440 (both are 600etec summit ramps (440 high elev – 412 low elev)

850 G4 Pdrive ramps (not neccesarily summit)

Bog on bottom end; 700 based from a 600RS engine

From: Aaron Exxx III [mailto:aaronexxx@gmail.com]

Sent: Wednesday, January 6, 2021 12:26 PM To: joe

Its a 2013 xrs 120 but it has a ported 700 based from a 600RS engine. 40mm rack carbs 600 sdi pipe. 1.25 track 120 . 126 studs 25/45 gearing

It made 75hp to the track on Goodwin dyno.

It runs really well and a brand new 2021 850 etec can’t pull on me from a roll.

Hence the problem i am having .

I was getting pipe surge testing in a field before the dyno and on the dyno.

Down jetted it to 400 mains on the dyno and 11.6 afr on the wideband but had to load up the pin weight to 21.7 grams to get rid of the pipe surge .

Can only rev 7600 now versus the 8k its designed for but still runs well at the 7600 on the dyno tach and digital premium gauge.

Problem is I can’t do shit out of the hole as there is just too much pin weight for the 200/310 spring I have in it which is why I just ordered this spring to try.

414 ramps clicker 4 44/42 helix with a 180/303 spring.

Any insight ? maybe notch the start if the ramps ?

Thanks Joe ! Aaron

REPLY

Hi Aaron. The 414, 413, 415 ramps are the same ramps except the first ¼ of the shift.

Get a set of 415 ramps and directly change them out.

Do nothing but change them out. They’ll give the engine a chance to be a bit more revvy on the bottom end.